Quality Production by Spronken is a orthopedic insole factory with 60+ years of experience. We produce over 15,000 pairs of custom orthopedic insoles annually in our workshop/studio in Genk.

We offer a wide range of products that comply with ISO 13485 and MDR quality standards. Each insole is delivered with a unique passport.

Our Custom insoles undergo extensive testing and formal final inspection. For orthopedic and podiatric insoles, we test the strength of the insole. For sports and safety insoles, we test shock absorption and elasticity. In addition to safety and aesthetics, the product can only be packaged after passing the final inspection.

QpLine®

Delivery of Measurements

Currently, there are two physical methods to provide us with your measurements: an imprint in a foam box or a blueprint. Occasionally, plaster casts are also processed.

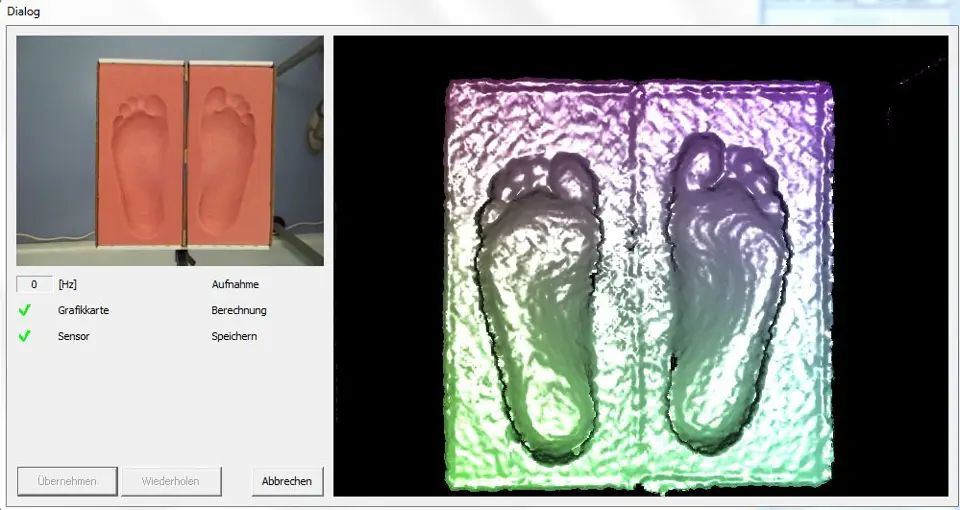

The imprint in the foam box is scanned using a 3D scanner, resulting in a digital impression. Similarly, a blueprint is digitized using a scanner.

With CAD/CAM software, the orthotic is digitally modeled, even if you have opted for a traditional orthotic. We digitize all imprints so that we always have the impression of your patient available for adjustments or additional orders, for example.

Through the digital method, 3D scans (STL files), 2D scans (BMP files), or images of your pressure mat can be used to manufacture the orthotic.

If you already have a specific scanner available in your practice, you can continue to use it. This file, along with the measurement chart, can be sent to Quality Production. The orthotic can be modeled using CAD/CAM software based on this scan, or a traditional orthotic can also be made.

Type of insoles

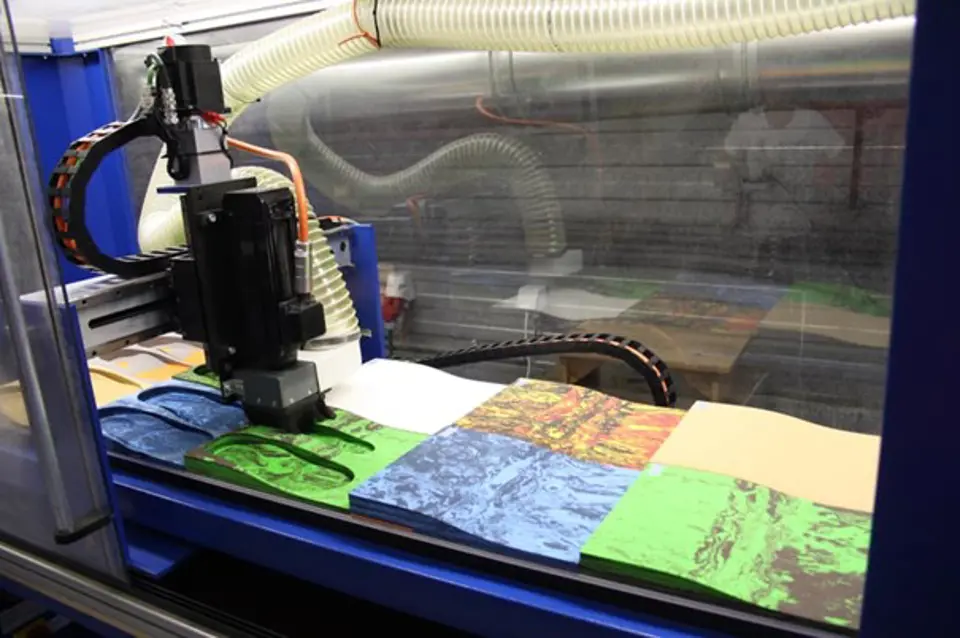

The QpLine Support® is a 3D-milled orthotic that is modeled using CAD/CAM software.

3D-milled orthotics provide an innovative way to offer custom-made orthotics for individuals. This technology ensures a more precise fit compared to traditional construction methods.

All adjustments, corrections, and features are digitally modeled according to the customer's specifications.

3D-milled orthotics are ideal for full-contact orthotics and orthotics for individuals with heavier weight.

We offer various types of milling blocks, and the corrections are integrated into the orthotic.

| 25° | 40° | 25° + 40° | Cork + 25° voor | Cork + 25° vol |

| Extra soft | Sport | Soft | Cork | Cork |

|

|

|

|

|

There are various types of milling blocks available, and you can choose to model corrections or alternatively provide prefabricated corrections on the milled insole afterwards.

The QpLine Elegant® is a hybrid orthotic and is the most requested orthotic due to its high patient satisfaction.

The QpLine Elegant® is a custom-made orthotic where the corrections (and elements) are milled from a thin EVA milling block. This is then bonded to a base model. It combines a traditional elegant base with a milled EVA milling block, resulting in a thin, elegant, and sturdy orthotic that easily fits into the patient's shoe.

With the hybrid orthotic, Quality Production offers a unique concept that minimizes the ecological footprint.

Just like with the milled orthotics, we have different hardness options available to manufacture the orthotic for your customer.

+

+  =

=

| 15° | 40° | Sandwich | Combi |

|

|

|

|

| Soft material | Medium material | Combination of soft base layer and medium top layer. | Combination of hard heel (corrections) and soft forefoot (elements). |

The QpLine High Heels® is the most innovative insole on the market.

Suffering from painful feet during and after wearing high heels? We have the perfect solution for your patients!

Our innovative QpLine High Heels® are specially designed for women who wear high heels. These elegant insoles provide the necessary extra cushioning for the forefoot and support for the arch. Customers and their patients rave about the QpLine High Heels®, so why not give them a try.

A new insole like never seen before - an innovative combination of technology and foot care that will surprise both customers and medical professionals. With this product, you can truly make a difference.

A traditional insole is constructed from different materials and elements. It starts with a base model and is built up with the desired features. Using this method, the insole is completely handcrafted.

Type coverings

Quality Production offers an extensive range of covering materials.

| Name | Photo |

Type of covering |

|

Dryfeet beige |

|

Dryfeet |

|

Dryfeet black |

|

Dryfeet |

|

Leather beige |

|

Leather |

|

Leather zwart |

|

Leather |

|

Foam blue flamed |

|

Foam |

|

Foam blue/gray flamed |

|

Foam |

|

Foam pink flamed |

|

Foam |

|

Foam multicolor |

|

Foam |

|

Foam black flamed |

|

Foam |

|

Foam black |

|

Foam |

|

X2 + dryfeet (diabetic) |

|

Dyafoam + Dryfeet |

Are you looking for custom-made orthotic insoles that meet the unique needs of your customers? Look no further!

Our team of experts specializes in creating tailor-made orthotic insoles for every situation. We understand that everyone's preferences are different, and we strive to provide the best possible solution for every podiatrist, orthopedic provider, and instrument maker.

Contact us today to find out how we can help you provide your customers with the perfect orthotic insole for their needs.

Practical Information

The orthotic insole department of Quality Production manufactures orthotic insoles within 5 working days. If expedited delivery is required due to urgency, we are flexible and will do our utmost to provide faster delivery.

Each orthotic insole is accompanied by a certificate and undergoes a comprehensive quality control before leaving the workshop/studio.

"Our customers are our partners. Together, we deliver an outstanding product to the patient."